The custom AHU manufacturing industry is changing. It’s not changing because it wants to change. It’s changing because the world is changing, and manufacturers need to evolve to stay competitive.

New technologies, new competitive forces and new regulatory environments are all exerting pressure on manufacturers to become more responsive and more efficient. Manufacturers are starting to take a serious look at shaking up the way things have been done for decades and embarking on a digital transformation that is often referred to as Industry 4.0 to meet these challenges.

What Is Industry 4.0?

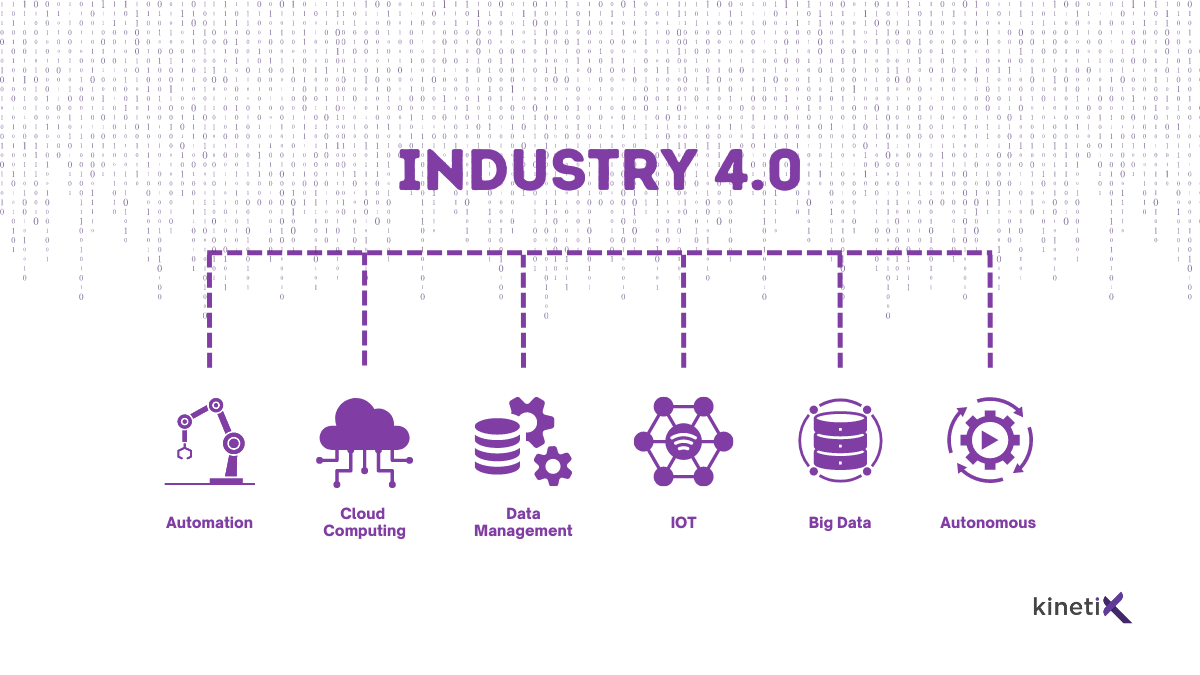

“Industry 4.0” started to be thrown around as a buzzword coined as part of the German government’s development strategy nearly a decade ago. It refers to digital transformation as a fourth industrial revolution. Today, this digital transformation is becoming a reality across many industry categories.

Concretely, what it refers to is the networking of cyber-physical systems, encompassing the linking of operational technology (OT) and information technology (IT), the development of the internet of things (IoT) and the push toward big data analytics, as well as cloud and remote computing, all in order to create a unified digital space for a company to operate in. This transformation aims to drive increased efficiency, faster production, greater customization and improved agility and responsiveness through smart, connected manufacturing.

Current State of Play

It’s no secret the current AHU sales, design, and build process is siloed, repetitive and, let’s be frank, not very dynamic.

Teams across your organization pass each other the ball throughout the process and use separate, often incompatible systems to move each AHU unit from the sales team through to the design team and onto the production floor.

Each team has to create their own documentation. If they need to consult, detailed emails fly back and forth, and with all the repetitive data entry, errors can easily work their way in. But it doesn’t have to be that way.

To move toward the vision of Industry 4.0, organizations need to begin implementing unified platforms.

Don’t Invest in More of the Same

To transform the way the custom AHU design process works, manufacturers shouldn’t invest in more manufacturing space and staff. Instead, they should put their resources into re-engineering the way they design, sell and produce AHUs – unifying, automating, streamlining and accelerating their processes to become more efficient (and more profitable). Manufacturers that continue to rely on the old SOPs (standard operating procedure) won’t be able to scale up to meet new demands, severely limiting their marginal return on investment.

Why Change Your SOP Now?

After decades of successful operations using the same basic model, why should manufacturers suddenly care about re-engineering and industry 4.0?

The answer is growth. Demand for custom AHUs is growing, and the most efficient, responsive and capable manufacturers will be the ones who end up capitalizing on this new demand.

What’s Driving This Growth?

On a micro level, explosive demand for new projects has been driven by data centers and the fast-growing cannabis industry, but on a macro level, there is a massive amount of retrofit business already here, with demand ready to skyrocket as new regulations take effect.

Both COVID-19 and climate change are driving new standards for air cleanliness and energy efficiency, pushing governments and regulating bodies to reassess the entire industry. The majority of AHUs will need some sort of retrofit, if not a complete redesign, to cope with the new realities.

The compound annual growth rate (CAGR) for new and retro-fitted AHUs is currently sitting at 6.5%, with the Asia-Pacific region leading the way, and according to recent research, the custom commercial AHU segment of the AHU market (hospitals, manufacturing cleanrooms, universities, shopping centers, labs, data centers, etc.) is predicted to be the fastest-growing market segment from now until 2026.

The reality is that current industry operating practices are hopelessly inadequate to handle this massive jump in demand, and the future belongs to the companies that can best adapt to these new realities.

The AHU Market Is Being Challenged

Though demand is increasing, production costs are also moving up quickly. To meet this new demand and stay profitable, AHU manufacturers are facing some common challenges that we are going to talk about shortly.

There is also intense competition in the market due to the presence of many regional and international players. Vendors are under constant pressure to deal with price fluctuations and retain their competitive edge in the market.

- Many HVAC manufacturers* have already increased prices in 2022, making headlines as another round of price increases go into effect this year.

- Across the board, we are seeing manufacturers raise the cost of equipment, parts, and supplies from 3% up to close to 20%.

- Increases are due to a multitude of factors that are driving inflation, including raw material costs, increased labor rates, fuel and transportation costs, and supply chain issues.

4 Key Capabilities of Kinetix Air to Help You Attain Industry 4.0

In order to move toward the goal of Industry 4.0, today’s AHU manufacturers need four key capabilities that they typically do not have access to today. Current selection software is limited to the selection process; it does not integrate with other systems throughout the production process, and is seldom even networked to allow for collaboration.

Going forward, integration and collaboration will bekey to improving efficiency and boosting capacity sufficient to meet new demands.

We’ve been talking to AHU manufacturers for more than three years now. Here is what is at the top of their wishlist:

Capability 1: Getting a fast start on new projects and maintaining that velocity throughout the entire manufacturing process

Capability 2: Putting an end to rework

Capability 3: Effective sharing and collaboration

Capability 4: Developing a single source of truth

Many manufacturers tell us they are hitting a productivity wall working in the fragmented and siloed paradigm that has become standard operating procedure in the industry. With demand ramping up, manufacturers are looking to improve productivity without massive investments in new manufacturing infrastructure and human resources.

Kinetix Air to the Rescue

That is where Kinetix Air holds the key. Adopting the Kinetix Air platform can enable custom AHU manufacturers to handle 10x the amount of business they have handled in the past, all because it provides each of these core capabilities. Let’s dig into the details:

Project acceleration

Currently, most manufacturers treat each project as a one-off, and there is very little leveraging of past projects – and that is mostly due to limitations in their selection software platforms. But even though each design is custom, they do have common elements, and some projects are more evolutions than revolutions of past designs. Every manufacturer we’ve spoken to has expressed the need for the ability to bootstrap new projects in order to fast-track initial design and leverage all the important work done during the design phase throughout the production process.

Manufacturers need smart software like Kinetix Air to build efficiencies by leveraging existing projects to accelerate toward design instead of wasting time on the setup process, again and again and again.

Eliminating repetitive tasks

If you are in the industry, you know how painful the transition from initial design to sales to submittal to manufacturing can be – with hours of time spent on manual validation, re-entering data and, of course, the inherent risks of human error. The ability to have a unified, end-to-end process is a holy grail for custom AHU manufacturers – and they’ve told us so!

Kinetix Air provides the capability to use the data generated during the initial design and sales phases to drive order entry, submittal package development, the creation of the bill of materials (BOM), and even after-sale service and maintenance. This is a key capability in re-engineering AHU manufacturing and moving toward Industry 4.0.

There are also quality of life improvements to consider.These days, good talent is hard to find, and improving the overall AHU selection process experience for your engineers and designers is a key factor in reducing turnover and ensuring the tenure of talent.

Modern Cloud Collaboration

Streamlined communication and collaboration are also key productivity boosters. You know the hassle and time wastage involved in project communications. Emailing project documentation to manufacturers’ reps, clients, and construction firms and then manually re-entering any feedback and changes and trying to keep track of versioning drives wasted time, miscommunication, stress, and human error. Sharing current project documentation, collaborating on projects and communicating via a unified cloud platform, while also being able to track who is working on a project and what stage it’s at, provides a huge productivity boost. It is a core capability, and it’s something on almost every manufacturer’s punch list.

In fact, a 2017 study of 1,100 companies by the Institute for Corporate Productivity and Professor Rob Cross of Babson College in Massachusetts found that those promoting collaborative working were five times more likely to be high performing. With Kinetix Air’s seamless collaboration capabilities, your teams can work together on multiple projects in multiple locations, dramatically boosting productivity.

Single Source of Truth

Another inefficiency that drives time, cost, and frustration for custom AHU manufacturers is the need to manually manage cost model, validation parameters, and other basic data sources that are used regularly across all projects. Searching for costing calculations and copying and inserting them in your current project spreadsheets is slow, painstaking work.

Manufacturers have repeatedly told us they need a single source of truth for components, pricing models, validation parameters, and all the base data required for every project. And more than that, they need an in-house content management system, which allows them to manage and update the data and models quickly and easily. The selection software in use by most firms today includes component data but stops short of centralizing and standardizing the pricing and validation models required to complete the sales process.

And finally, that single source of truth needs to be the basis for a unified workflow that rationalizes your process to improve the way everyone works and drive better bottom-line performance. Kinetix Air provides that single unified source of truth, including the capability to change pricing platform-wide. Kinetix Air is the solution manufacturers need to accelerate and optimize their processes.

Automate, Accelerate and Optimize with Kinetix Air

Kinetix Air is a radical rethinking of AHU selection software. The platform accelerates the design process and automates validation, costing, submittal, and bill of materials, and radically reduces risk of human error – allowing your teams to collaborate on all phases of the design and manufacturing process. Make it a key part of your business’s strategy and be among the first to benefit from industry 4.0.

Traditional selection software only does part of the job. Kinetix Air unifies all aspects of custom AHU design and automates the repetitive and time-consuming parts of the process – cutting your level of effort and reducing risk from errors. Talk to us to find out more about how Kinetix Air can help.